CONTUFILT-M

Precious Metal Catalyst Filtration

Save huge catalyst losses using closed systems.

Pharmaceuticals, APIs (Active Pharmaceutical Ingredients), and chemicals use heterogeneous precious metal catalysts. Conventional filters with manual handling have catalyst losses in every batch. CONTUFILT-M recycles the precious metal catalyst with minimal losses and pays back CAPEX in a few months by the catalyst saved

Process Operation

Filtration made easy.

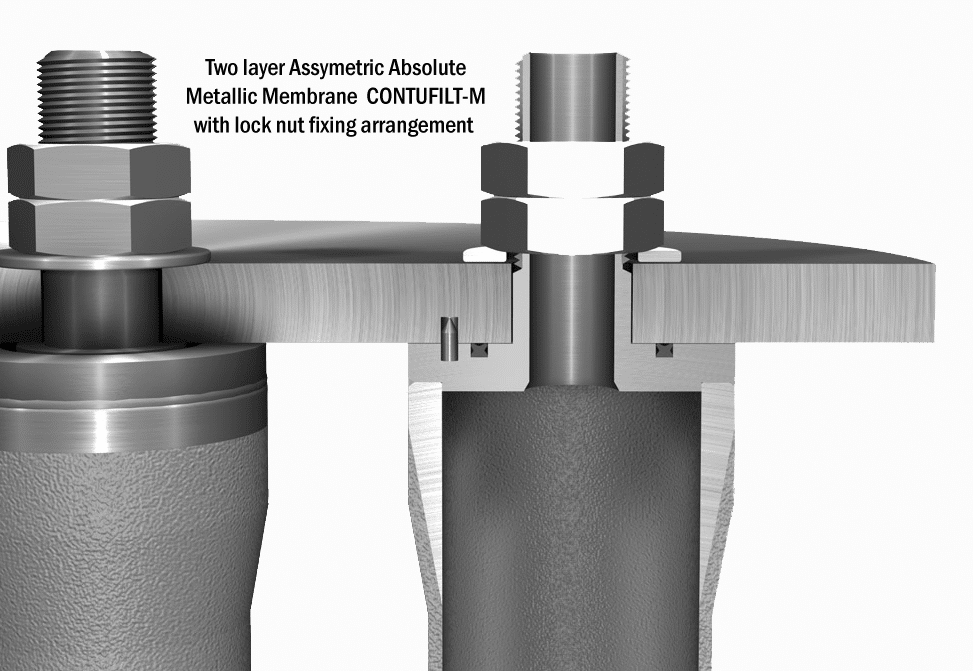

The system comprises filter candles made up of our Vacuum fused Metallic open channel proprietary media, suitable for Precious Metal Catalyst filtration.

Candles are placed on a tube bundle in a housing. We perform specific filtration functions, in-situ reverse flow, washing, and gas-assisted discharge of collected catalyst particles. The cake is collected in semi-solid form or is sent as a slurry. The candles are clean and ready to use for the next operation.

The new ZERO HOLDUP bottom design ensures that complete liquid is removed from the vessel, very important for API manufacturing where GMP does not allow mixing of batches, nor any liquid holdup is permitted. Full liquid recovery is achieved, and the catalyst particles are purged out of the system without opening the system.

Features and Benefits

Catalyst-Friendly Closed System

Preserving Catalyst Activity: Operates within a fully closed system that maintains catalyst activity unaffected.

Minimized Catalyst Losses

Enhanced Catalyst Conservation: Reduces catalyst losses, optimizing usage and cost-effectiveness.

Chemical Durability

Defying Harsh Elements: Withstands aggressive solvents, oxidants, and various chemicals for reliable performance.

Energy Efficiency & Backwashing

Economical Energy Usage: Achieves reduced energy costs through efficient backwashing processes.

Scalable Modular Design

Adaptable Scalability: Incorporates a modular design with ample scalability options, allowing system expansion as needed.

Consistent Flux Repetition

Reliable Flux Repeatability: Maintains consistent flux levels, contributing to dependable and reproducible results.

Robust Mechanical Strength

High Solid Loading Tolerance: Exhibits excellent mechanical resistance, enabling handling of high solid loading for longevity.

Applications

Different Applications of Precious Metal Catalyst Filtration

- Platinium or Palladium Catalysts

- Catalysts for Hydrogenation and Selective Oxidation

- Supported Homogeneous Catalysts

- Precious and Base Metal Heterogeneous Catalysts

- High Dispersion Catalysts

- Hydrogenation

- Chiral Catalysis

- Chiral Ligands

Asymmetric Synthesis

- Asymmetric Hydrogenation

- Asymmetric Hydroamination

- Asymmetric Alkyne addition

- Asymmetric Michael reaction

- Asymmetric Ene Carbonyl

- Asymmetric Diels-Alder and Hetero Diels-Alder

- Asymmetric Cyclopropanation – Lactone synthesis

- Continuous Filtration Of Fine Suspensions

- Concentration Of Solids

- Closed And Safe Filtration Process (e.g., Pyrophoric Catalyst Filtration)

- Surface Filtration Without Filter Aids

- Fully Automated Filtration Processes

Diva Filtec is an engineering company specializing in diverse process improvement technologies for various industries.

Contact

Industry

Quick Links

- Director's Desk

- Trademark Details

- Career

© 2024 Diva Filtec Pvt Ltd. All Rights Reserved.