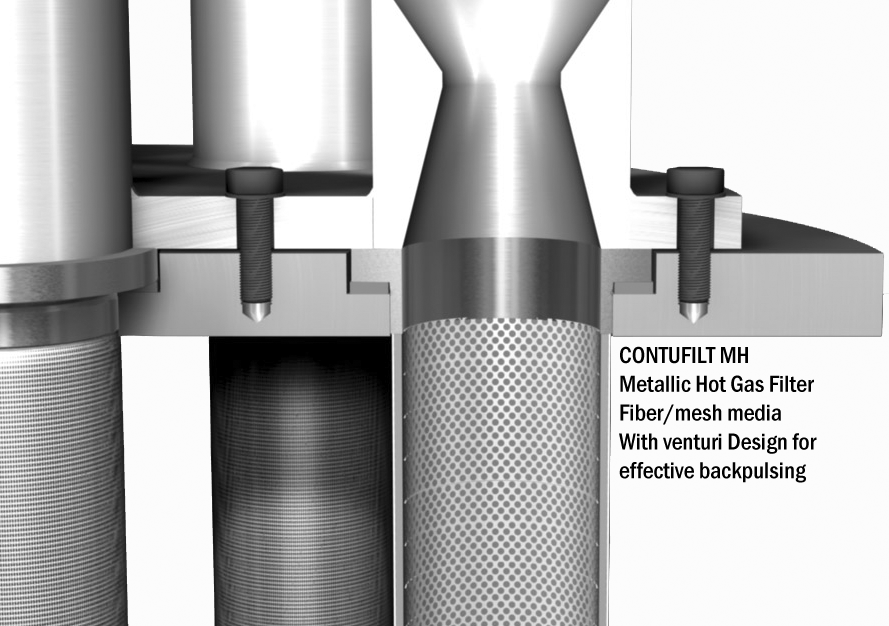

CONTUFILT-MH

Hot Gas Filtration

Separating solids in hot corrosive environments

Gas reactions are carried out in the presence of precious metal catalysts. Processes generate particles and the gases which are vented carry solids with them. These solids have to be recovered. CONTUFILT-MH metallic filters avoid poisoning of catalysts or recovery of products from the off-gas.

Hot gas filtration in chemical processes is of prime importance to keep the contaminants away. One such example out of many is Nitric Acid. The production of Nitric Acid requires an NH3/ Air mixture to be filtered to protect the expensive catalyst beds which are the oxidation zones in the reactor. The filtration is very critical as it helps reduce downtimes and safeguards the expensive noble metal catalysts. Other industries also use hot gas filtration down to micron levels. We will work closely with you to find a cost-effective and reliable solution.

Process Operation

The system comprises filter candles made up of our Vacuum fused Metallic open channel proprietary media, suitable for fine particle retention

Candles are placed on a tube bundle in a housing. We perform specific filtration functions, back pulsing and gas-assisted discharge of collected particles.

Technical Specifications

- Housing designs from a few bars to 100 Bar pressure rating

- Materials of construction include carbon steel, stainless steel and special alloys

- Housings are available with connection inlet outlet size ranges of 25 mm to 300 mm

- Available micron ratings from 0.3um onwards

- High-pressurere vessel fabrication facility to manufacture as per DIN/ASME standards, U-Stamp available

Features and Benefits

Hot Gas Particle Removal

Effective Hot Gas Filtration: Specialized for extracting particles from compressed hot gases, enhancing gas purity.

Versatile Filter Media

Diverse Filtration Options: Choose from Sintered Powder, SS Fiber mesh, or special alloys for fine filtration versatility.

Catalyst Protection

Safeguarding Catalyst Integrity: Prevent precious metal catalyst poisoning, ensuring optimal performance and longevity.

Backpulsing Capability

Easy Cleaning Process: Facilitates backpulsing for convenient and thorough cleaning, maintaining filter efficiency.

Minimal Pressure Drop

Efficient Flow Dynamics: Experience minimal pressure drop (Delta P), optimizing energy consumption and system performance.

Rapid Flow Rates

Enhanced Gas Flow: Benefit from high flow rates, promoting efficient gas movement through the system.

Applications

Explore the Diverse Applications of Hot Gas Filtration

- Nitric Acid manufacturing NH3/Air mixtures

- Melamine Anhydride manufacturing

- Polysilicon Hot gas in Process

- Atmospheric Pollution Control (APC)

- Incineration Plants Chemical + Clinical Waste

- Dry Gas Scrubbers

- Soil Remediation

- Aluminum smelters

- In-Line Equipment Protection – (ILEP)

- Biomass Gasification & Pyrolysis

- Catalyst Protection

Diva Filtec is an engineering company specializing in diverse process improvement technologies for various industries.

Contact

Industry

Quick Links

- Director's Desk

- Trademark Details

- Career

© 2024 Diva Filtec Pvt Ltd. All Rights Reserved.