MSDF

Continuous Slurry Thickners

Concentrating difficult to filter slimy particles

Very low concentration slurry streams with slimy and sticky solids often have to be concentrated. Filter presses frequently choke, making the operations cumbersome. MSDF moves from conventional filter press to spin filtration, offering an improved cleaning effect on the filter surface by rotation and a reduced energy cost.

Operation

MSDF membrane systems operate using membrane disks of different MOC configurations in modular stack mode on a rotating shaft. That separation technology relies on the differences in physical sizes in the MF range and the molecular weight (size) of the individual components when processing in the MF and UF range. Very similar to our PORESEP range, this system does not use cross-flow filtration.

MSDF is best used for continuous filtration where the slimy solids form a secondary resistive cake or layer. The rotary action of the disc brings a low shearing and continuous cleaning of the filter surface. The relative motion between the medium to be filtered and the filter is not generated by pumps but instead by the rotation of the filter elements

or a rotation of flow disrupters. It is low on energy consumption as it overcomes the high pumping required in conventional cross-flow systems.

Benefits

Explore various Benefits of Continuous Slurry Thickners

- High-temperature resistance (0-130 ºC) with a varied range of membranes starting from Polymers to Ceramic to SS membranes

- Broad pH range (0-14)

- Surface filtration

- Fully closed System

- Resistance to aggressive solvents, oxidants and most chemicals

- Steam Sterilization (autoclave, oxidant, etc.)

- Extremely high cross flow velocities – with no filter blocking

- Reduced energy costs compared to conventional cross-flow systems

- Modular design with extensive scalability options

- Repeatability in fluxes

- Excellent mechanical resistance (High Solid loading)

Features and Benefits

Chemical Durability

Defying Harsh Elements: Withstand aggressive solvents, oxidants, and a wide array of chemicals for durable performance.

Versatile Sterilization

Sterilization Flexibility: Suitable for various sterilization methods including autoclave and oxidant treatments, ensuring hygienic operation.

Energy Efficiency

Lowered Energy Consumption: Experience reduced energy costs while maintaining optimal functionality.

Scalable Modular Design

Customizable Scalability: Adapt the system to your needs with a modular design that allows for easy expansion.

Consistent Performance

Repeatable Flux Performance: Ensure consistent and reliable flux rates, contributing to dependable outcomes.

Robust Mechanical Strength

Tackling High Loads: Excel in handling high solid loading thanks to excellent mechanical resistance, ensuring longevity.

Technical Specifications

Membrane types are available and suitable for various applications and process conditions.

Modular Design: Area – 1 sq. mts to 100 sq. mts

UF/MF MEMBRANES: PP, SS, Ceramic

MW Cut-Off or Micron : 1,000 MW, 5,000 MW, 10,000 MW, 20,000 MW, 25,000 MW, 30,000 MW, 50,000 MW, 100,000 MW,

120,000 MW, 0.05 Microns, 0.1 Microns, 0.2 Microns, 0.45 Microns, 0.65 Microns, 0.8 microns, 1.2 microns, 3.0 microns.

Process Operation

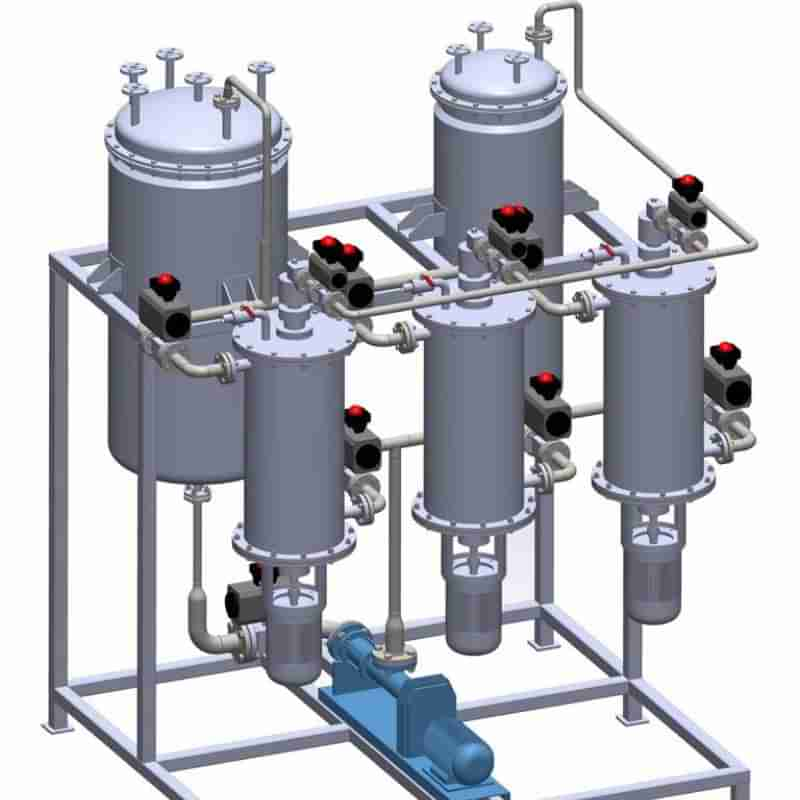

The system consists of a number of equally sized pressure vessels each containing an equal area of Porous multi-layered mesh metal cartridges arranged in triangular pitch or distance suitable for applications. The vessel performs the specific functions of filtration, in-situ reverse flow, gas assisted discharge of collected dirty pre-coats and when required, an in-situ soak to re-slurry the pre-coat / solid cakes if required.

The mechanism of filtration is a direct interception of pre-coat solutions on the surface of the Porous mesh plate metal filter. This initial capture starts and enhances the capture of all other particles building a pre-coat cake. Normally there is no need to re-circulate the liquid to achieve clarity as this micron rated multi-plate sintered mesh media gives instant clarity in a single pass. Sometimes to assist the filtration in difficult to filter masses a body feed with the necessary grades of keisulguhr, perlites, Filter-cel are used and then the ongoing formation of a surface cake continues to build- up to a depth of 10 mm or greater depending on the cake resistance and characteristic. Complete recovery of liquids is achieved and the particles are purged out of the system without having to open the system.

Applications and Uses

Explore the Diverse Applications of Continuous Slurry Thickners

- Chemical Pharmaceutical IndustryOrganic solvents colour removal

- Hazardous chemical closed-loop filtration

- Activated Carbon filtration

- Precious Metal catalyst recovery

- Paper Industry

- Resource recycling

- Closed-loop techniques

- Sieve water paper mills

- Paints, pigments, adhesives

- Pigments desalting

- Solvent recycle

- Lacquer de-watering

- Water-soluble glue concentration

- Waste Water Treatment

- Clarification of Effluent water reduction of NTU

- Slurry concentration & washing

- Digested sludge separation

- Water recycling

- MBR / aeration

- Sparging

Diva Filtec is an engineering company specializing in diverse process improvement technologies for various industries.

Contact

Industry

Quick Links

- Director's Desk

- Trademark Details

- Career

© 2024 Diva Filtec Pvt Ltd. All Rights Reserved.