NANOPOREX

Sparging of gas in liquid streams

Bubbles improve process efficiency increasing mass transfer 600 times

NANOPOREX bubble generators introduce finely dispersed gas bubbles into the water, significantly enhancing mixing and expanding the surface area available for gas-liquid mass transfer. This innovative approach leads to heightened efficiencies in both chemical and biological processes. The Nanoporex bubble generator increases the mass transfer surface area almost 1000 times more than drilled pipe or diffusers conventionally used in Industry.

Process Operations

The gas is dispersed as a fine mist of bubbles, increasing the mass transfer area. When liquid-gas interphase reactions occur, the heightened surface area improves gas-liquid mixing efficiency.

Features & Advantages

NANOPOREX bubble generators use cavitating devices to create billions of fine bubbles.

Increase the surface area in a two-phase reaction between gases and liquid, achieving very fast, efficient mass transfer.

Bubbles for Efficient Processes in Various Industries

Mining

Bubble technology enhances aeration in wastewater, tailing ponds, and acid mine drainage treatment.

Ideal for separation processes like froth flotation and heap leaching in metal extraction.

Plug-and-play bubble generators maximize efficiency in heap leaching and froth flotation.

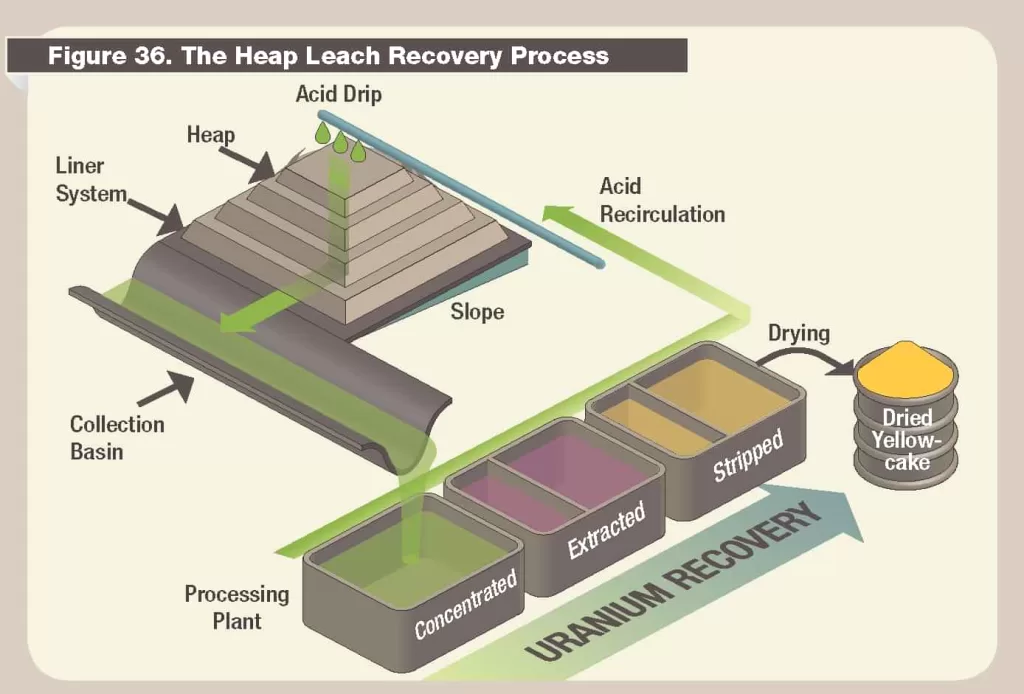

Heap Leaching

Bubbles efficiently deliver oxygen into the leaching process, improving metal recovery.

Proprietary gas-injection technology integrates seamlessly with leaching irrigation systems.

Enhances metal recovery and lowers leaching costs for gold, copper, uranium, and more.

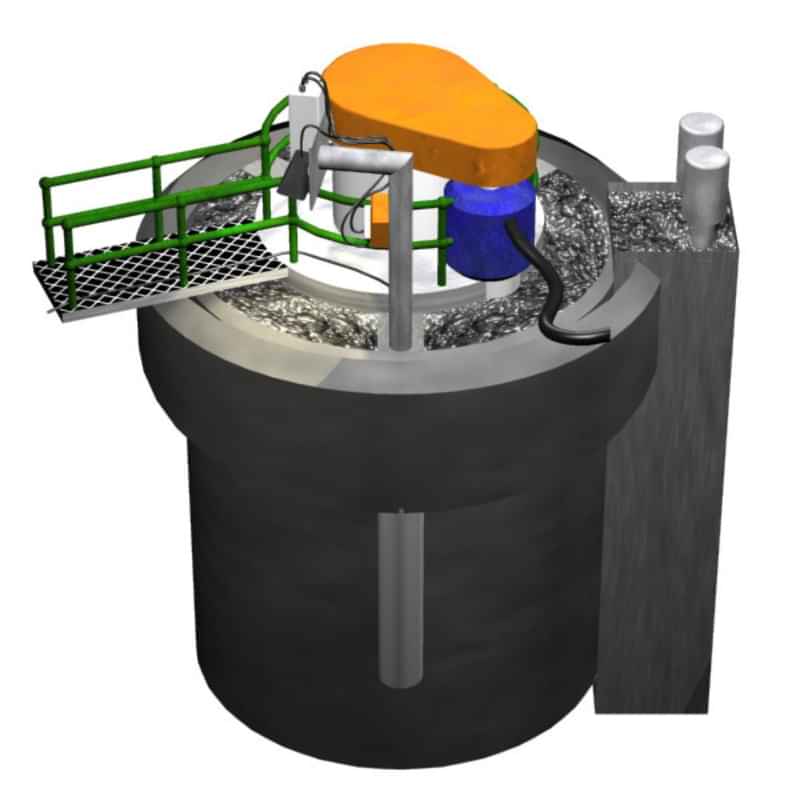

Froth Flotation

Bubbles increase collision efficiency, accelerating the flotation rate of particles.

Facilitates the separation of solid particles based on physical and surface chemistry properties.

Offers a side-by-side comparison showcasing the effectiveness of bubbles.

Dissolved Air Flotation (DAF)

Bubble Systems’ gas-injection technology significantly improves the flotation process.

Reduces energy consumption by 10%-20% compared to conventional methods.

Unique properties ensure compliance with environmental regulations.

Better Collision, Rise Rate Flexibility, Improved Chemical Efficiency

Bubbles’ negative surface charge prevents coalescence, ensuring effective interaction.

Adjustable gas-injection rate allows operators to manipulate bubble size and rise rates.

Bubbles increase collision rates, reducing the quantity of chemicals needed for flotation.

Lakes & Pond Remediation (Algae Control)

Bubbles cost-effectively prevent harmful algae blooms in lakes and ponds.

Maintains dissolved oxygen levels throughout the water column, independent of depth or temperature.

Chemical-free treatment eliminates and prevents algae without the use of herbicides.

DO Mixing and Distribution

Bubbles evenly oxygenate the entire water column, preventing hypolimnion anoxia.

Neutral buoyancy ensures adequate oxygenation of the sediment, improving water clarity.

Non-invasive Plug & Play Solution

Bubble generators, positioned outside the water body, offer a simple installation process.

Eliminates and prevents algae more cost-effectively than traditional aeration systems.

Aquaculture

Bubble technology addresses the challenge of low dissolved oxygen levels in fish farms.

Improves stocking density, disease prevention, and overall fish health.

Cost-effective oxygen transfer ensures efficient aquaculture operations.

Disease Prevention

Bubbles prevent disease by providing clean and natural oxygen to fish and mollusk populations.

Cost-effective and healthier alternatives to traditional methods like vaccination and antibiotics.

Horticulture & Hydroponics

Bubbles enhance oxygen transfer, benefiting plant health and growth.

Increased yield, healthier roots, and enhanced growth rates in horticulture applications.

Cost-effective and efficient gas-to-liquid injection technology for crop cultivation.

Increased Yield

Bubbles with elevated DO levels result in higher root mass and efficient nutrient absorption.

Healthy roots contribute to enhanced growth rates, reducing growth cycle time for increased revenue.

Waste Water Treatment

Bubbles provide cost-effective supplemental aeration for membrane bioreactors (MBRs).

Effective in controlling odors, preventing anaerobic conditions, and maintaining high DO levels.

Modular and quick solution for enhancing treatment efficiency in various water and wastewater processes.

Membrane Bioreactors (MBR)

Bubbles offer supplemental aeration during peak loading events, ensuring consistent DO levels.

Cost-effective solution for maintaining target DO levels in industrial MBRs.

Odor Control

Bubbles efficiently maintain dissolved oxygen, preventing anaerobic conditions that lead to odorous compounds.

Effective treatment for offensive odors, particularly hydrogen sulfide, in wastewater.

Oil & Gas

Bubble technology improves oil-water separation efficiency and reduces hydrogen sulfide (H2S).

Cost-effective and efficient treatment methods for the oil and gas industry.

Oil-Water Separation

Bubbles enhance flotation, facilitating the separation of oil and suspended solids.

Ideal for treating produced water in oil refineries.

Technical Specifications

- Sintered metallurgy which is vacuum fused, bringing in ductility and strength

- Temperature range as high as 450 deg C under oxidising and 550 Deg C in reducing atmospheres

- Recommended pore size 3 – 10 μm with no seams on the porous body

- Customized flow rates and design

- Long lifetime

- High flow rates

- Ring microniser available (min dia. 200mm)

- A broad range of alloys available – including 316L, 304, stainless steel (standard), PP, PTFE , PVDF , Nickel, Titanium, Monel® 400, Inconel® 600, Hastelloy® C-22/C-276/X, 321 904L etc.

- Customized end fittings

Applications and Uses

- Aeration – Air sparging to meet BOD (Biological Oxygen Demand) on the waste stream.

- Agitation – Air injection for mixing liquids in a vessel.

- Bioremediation – Air sparging stimulates bacteria’s growth for hazardous waste treatment.

- Carbonation – CO2 sparging for carbonated beverages and beer.

- Chlorine bleaching – Chlorine sparging for bleaching pulp in the manufacture of paper.

- Froth Column flotation – Air sparging for Minerals and coal flotation for ore beneficiation

- Dewatering – Nitrogen sparging to remove entrained water from motor oil.

- Edible Oils – FFA removal / Oxygen removal to improve shelf life

- Fermentation – Oxygen or air sparging enhances cell growth in fermentation reactions.

- Gas/liquid reactions – Sparging air, oxygen, Chlorine or other gases into reactors for improved performance.

- Hydrogenation – Hydrogen sparging for a broad spectrum of chemical hydrogenation reactions.

- Induced Gas flotation – Air or natural gas sparging for oil removal from produced water treatment

- Oxygen bleaching – Oxygen sparging for bleaching pulp in the manufacture of paper.

- Oxygen stripping – Nitrogen sparging to remove oxygen from edible oils, wine, and juices.

- Inert Gas Blanketing in Solvent Storage tanks

- Oxygenation – Oxygen sparging in fish farming for significant stimulation of fish growth.

- Ozonation – Ozone sparging to sanitise ultrapure water systems in pharmaceutical plants.

- pH control – CO2 or NH3 sparging to adjust pH in waste or process streams.

- Steam injection – Direct steam injection for efficient heating and eliminating “steam hammer.”

- Gas stripping – Air sparging to remove VOC/ NH3 (Volatile Organic Compounds) from waste streams.

Diva Filtec is an engineering company specializing in diverse process improvement technologies for various industries.

Contact

Industry

Quick Links

- Director's Desk

- Trademark Details

- Career

© 2024 Diva Filtec Pvt Ltd. All Rights Reserved.