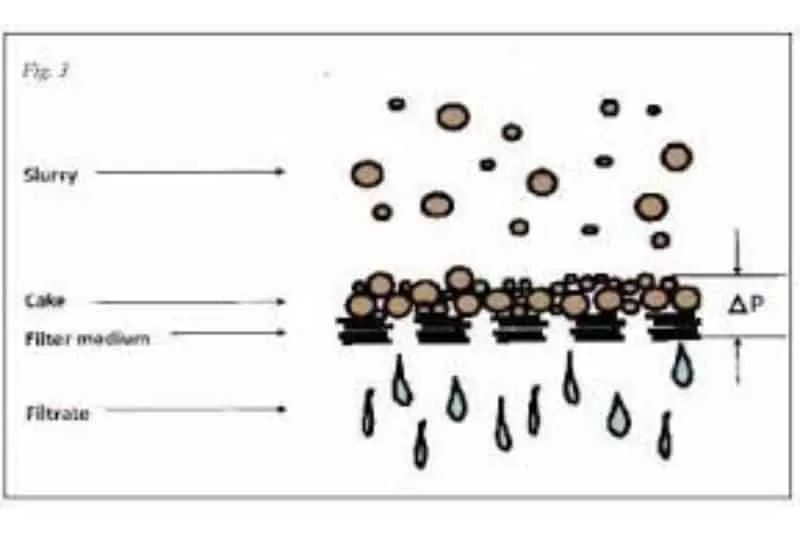

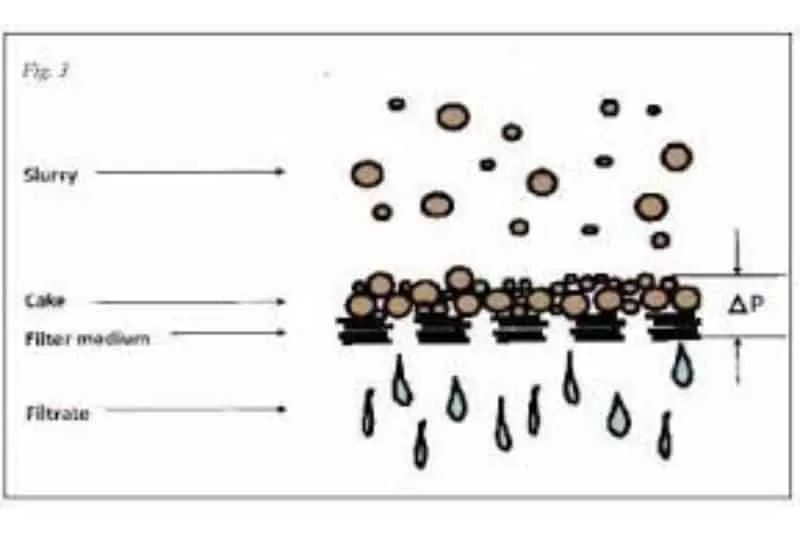

Unveiling Diverse Approaches for Slurry Filtration and Clarification in Industrial Processes

Slurry filtration and clarification are pivotal processes in numerous industries, significantly influencing the quality and efficiency of end products. The selection of suitable filtration and clarification methods is crucial and depends on various factors such as the type of solids, viscosity, density, and concentration in the solution. In this comprehensive blog post, we will explore different approaches for both slurry filtration and clarification, each tailored to address specific industrial requirements.

Candle Filters

– Ideal for high solids loading and high flow rates.

– Suited for slurries with elevated concentrations of solids.

– Commonly used in chemical and pharmaceutical industries.

Belt Filters

– Designed for continuous filtration of slurries with low to moderate solids loading.

– Effective for filtering slurries containing fine particles.

– Widely used in the mining and wastewater treatment industries.

Filter Press

– Suited for high solids loading and low flow rates.

– Effective for slurries with concentrated solids.

– Commonly used in the chemical and food processing industries.

Ceramic Filters

– Ideal for high-temperature applications.

– Suited for slurries with fine particles.

– Widely used in the mining and metallurgical industries.

Tubular Filters

– Suitable for high solids loading and high flow rates.

– Effective for slurries with elevated concentrations of solids.

– Commonly utilized in the chemical and pharmaceutical industries.

Clarifiers

– Designed for separating solid particles from liquid in large volumes.

– Effective in treating slurries with low to moderate solids concentration.

– Commonly used in water treatment, mining, and chemical industries.

Choosing the Right Approach

Selecting the most suitable filtration and clarification methods necessitates a thorough understanding of the specific requirements of the application. Factors such as the type of solids, viscosity, density, and concentration of solids in the solution play a crucial role in determining the optimal approach. Careful consideration of these factors ensures the efficiency and reliability of the slurry filtration and clarification processes.

Slurry filtration and clarification are multifaceted processes, and the effectiveness of the chosen methods directly impacts the overall success of industrial processes. The diverse approaches mentioned, including Candle Filters, Belt Filters, Filter Press, Ceramic Filters, Tubular Filters, and Clarifiers, cater to varying industrial needs. Understanding the unique characteristics of each method empowers industries to make informed decisions, resulting in enhanced efficiency and superior end-product quality.

Diva Filtec is an engineering company specializing in diverse process improvement technologies for various industries.

Contact

Industry

Quick Links

- Director's Desk

- Trademark Details

- Career

© 2024 Diva Filtec Pvt Ltd. All Rights Reserved.